We supply an integrated industrial chemistry training lab covers basic topics of industrial chemistry and enables students to explore chemistry of materials, including polymers, metals and nanosized materials, as well as of physical chemistry of formulations, industrial catalysis, energy conversion and storage and Pharmaceutical Industries.

The industrial chemistry training lab enables students to apply many experiments and activities such as:

- Ammonia preparation from the elements (Haber-Bosch process)

- Combustion of ammonia to produce nitrogen dioxide – Ostwald process

- Sulphur trioxide – the sulphuric acid contact process

- Electrostatic flue gas cleaning

- Cracking of hydrocarbons

- Determination of the heating value of fuel oil and of the calorific value of olive oil

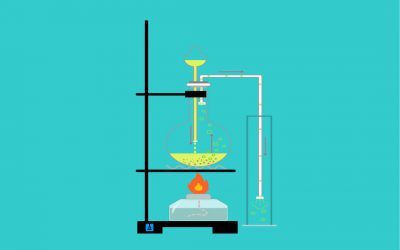

- Rectification – the number of theoretical trays in a distillation column

- Fractional distillation with the bubble tray column.

- Preparation of iron from oxidic ores (blast furnace process)

- Redox reactions between metals and metal oxides (thermite process)