We supply an integrated PLC training lab system, allows students to acquire hands-on experience with industrial control equipment. Realistic examples are used to motivate students. These examples are displayed on the graphic terminal, and correspond to real PLC applications that can be interfaced with the trainer.

The system comprises industrial components of the latest technology.

The lab also consists of many PLC applications training units that aim to further develop student understanding of PLC programming. Basic principles are integrated with more advanced concepts in order to design small-scale systems typical of what can be found in the industry. Through practical examples, students gain a strong knowledge of PLCs and of the studied applications. The PLC Applications units are including of Fault switches on selected modules to enhance troubleshooting activities by simulating open coils and contacts, defective contacts, shorted connections, and crossed wires.

The lab system enables students to apply various experiments and activities in PLC technology and applications covers following topics:

- Introduction to Manufacturing

- Familiarization with lab equipment

- Human-Machine Interface

- Machine Vision

- Servo Control

- FMS Production Line

- Automatic Storage and Retrieval System

- Electricity

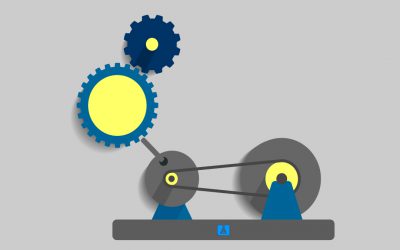

- Mechanics

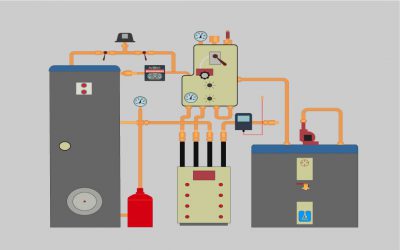

- Fluid Power

- Programmable Logic Controllers

- Advanced Subjects (artificial vision)

- Point-to-Point and Task Programs

- Program Editing

- Control Overview

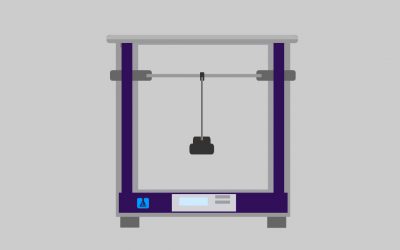

- Industrial Application Simulation Using a Gravity Feeder, Belt Conveyor, Pneumatic Feeder, Rotary Carousel or Linear Slide

.jpg)